We offer comprehensive process development solutions to identify and develop the most optimal process for your compounds including New Chemical Entities (NCE), advanced intermediates, and Key Starting Materials (KSM).

We keep customer's needs at the center of our planning. We understand our customer's requirements at every stage of the journey to the clinic. To meet these varying requirements, we follow a phase-appropriate process development approach. We design our processes based on customer needs. Our interdisciplinary team designs and demonstrates our capabilities in finding sustainable synthetic routes by considering the following concepts:

Reduced number of processing steps Reduced timeline for the scale-up Decreased cost by choosing the most efficient route Reduced chemical or reagent usage and waste production Avoiding expensive or difficult-to-handle raw materials Improved quality and safety profiles

Our execution operations and SOPs are very well designed to internalize the phase-appropriate delivery. Safety, Environment, Legal, Economics, and Control and Throughput (SELECT) principles are a key component of our process development strategy.

We carry out the process development at our state-of-the-art development facilities located in Hyderabad and Bangalore. This facilities are equipped to handle the development of small molecules, peptides, high potent compounds, steroids, carbohydrates and activated mPEGs. The same facility also provides formulation development, analytical method development & validation services and is equipped with a dedicated high potent lab and material generation lab with the capacities of 20L & 50L reactors for API functions.

Early stage

At an early stage, our focus is to accelerate the journey for the clinic to our customers through science and innovation. Our way of execution and processes ensures agility without compromising on safety, quality and sustainability. The focus at this stage is to ensure faster turnaround time.

Leveraging our vast experience in chemistry & process development, we have a unique advantage of identifying the most important process parameters.

To minimize the risk of failure at the GMP scale, we propose to perform one demonstration batch at our non-GMP kilo lab available at our development facilities.

Late Phase

We have a legacy of developing 500+ molecules, several of which are in the commercial phase in highly regulated markets like the USA, Europe, Japan, etc. We follow a very robust & systematic approach to process development. Our vast manufacturing footprint allows us the flexibility to choose from a variety of unit operations suitable for product manufacturing.

We follow a QbD-based approach for process development and the first step is to identify the key starting material and process parameters that impact the specification of the product. Our supply chain team helps in sourcing the raw materials with desired quality in time. For each stage, we plan a sequence of a well-designed set of experiments (DOE) to understand and establish the sensitivity of important parameters on quality.

We typically run 15-20 experiments per stage to arrive at the most optimum process. Post completion of these studies, three consecutive lab confirmatory batches will be performed to establish the yield & quality of the product.

The processes which are identified to be challenging for scale-up, are studied in our intermediate-scale non-GMP setup at our development facilities, before moving to large-scale manufacturing.

Why Aurigene Process Development Services?

Phase-appropriate development operations

Legacy of developing 500+ molecules

Horizontal capabilities like polymorph screening, material science, Qbd, PAT tools

Network of multi-scale R&D, NGMP, and GMP manufacturing facilities

Ability to handle various types of chemistry and technology platform

Value added services - regulatory & IP

US FDA approved R&D and manufacturing facilities

Connect with our scientific experts for your drug discovery, development, and manufacturing needs

We understand that clear communication is essential to successful collaborations, and that's why we have a dedicated team that is always ready to help you. Whether you have questions about our services, want to discuss a potential partnership, or simply want to learn more about our company, we're here to help.

Our team of experts is dedicated to providing personalised solutions tailored to your unique needs. So, please don't hesitate to reach out to us. We look forward to hearing from you and helping you achieve your business goals.

Resources

OCTOBER 01, 2024

PROTACs: Research for a life without cancer

PROTACs: Proteolysis-targeting chimeras (PROTACs) are a rapidly evolving field with promising applications in cancer, neurodegenerative diseases, and other conditions where the regulation of protein levels is crucial. PROTACs are a novel class of small molecules designed to target specific proteins for degradation by the ubiquitin-proteasome sys...

Read More

Advancement in personalized medicine and how the CRDMO industry is part of the solution

Personalized medicine is transforming the healthcare landscape by customizing treatment plans to individual patients’ unique genetic, clinical and environmental characteristics. These are effective and less invasive treatments for a wide range of conditions. Contract Research, Development and Manufacturing Organizations (CRDMOs) play an important role...

Read More

Cell Line Development

We enable development of stable and high yielding recombinant Mammalian and Microbial lines. ...

Read More

Case study: Tackling CYP 2C9 inhibition challenges

The Problem: Active compounds in a project were found to be highly potent inhibitors of CYP 2C9 The compounds selectively inhibited CYP 2C9 with IC50 values <100 nM There was no considerable inhibition of the other CYP isoforms Our Mitigation Approach: CYP 2C9 inhibition data was generated for a larger set of co...

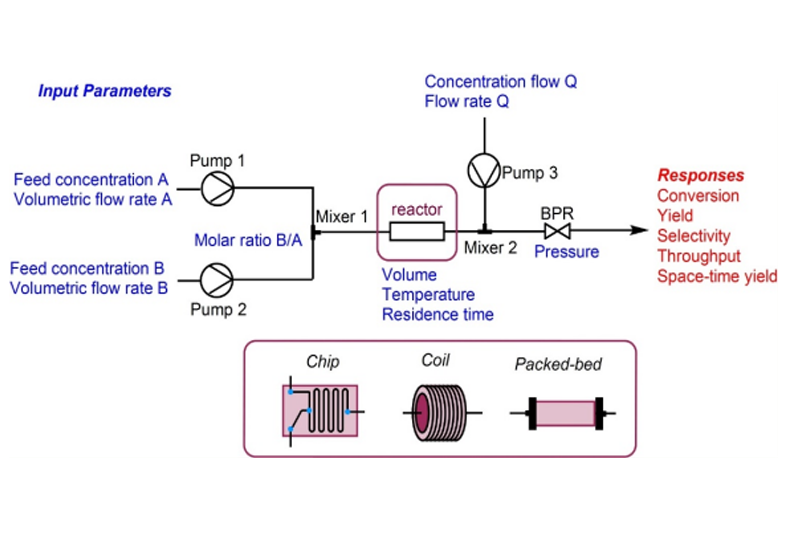

Read MoreSynthesis of Anti-covid Drug Nirmatrelvir Using Flow Chemistry

2022

Synthesis of the anti-covid therapeutic Nirmatrelvir by using flow chemistry to enhance efficiency of amide to nitrile conversion in a functionally and Stereochemically Embellished environment. ...

Read More-

Discovery of MAP855, an Efficacious and Selective MEK1/2 Inhibitor with an ATP-Competitive Mode of Action.

2005

Mutations in MEK1/2 have been described as a resistance mechanism to BRAF/MEK inhibitor treatment. We report the discovery of a novel ATP-competitive MEK1/2 inhibitor with efficacy in wildtype (WT) and mutant MEK12 models. Starting from a HTS hit, we obtained selective, cellularly active ...

Read More -

Wang-OSO3H catalyzed green synthesis of bioactive isoindolo[2,1- a ]quinazoline-5,11–dione derivatives: An unexpected observation

2005

The sulphonic acid-functionalized Wang resin (Wang-OSO3H) was explored as a polymeric and recov- erable acidic catalyst for the synthesis of isoindolo[2,1- a ]quinazoline-5,11–dione derivatives under green conditions. Thus the Wang-OSO3H ...

Read More -

Polycyclic Aromatic Compounds: A Simple and Efficient [(n-Bu3Sn)2MO4]n Catalyzed Synthesis of Quinazolinones and Dihydroquinazolinones

2005

A novel unprecedented approach for the synthesis of various quinazolinones and dihydroquinazolinones has been using [(n-Bu3Sn)2MO4]n as a catalyst. The reaction has been screened ...

Read More

You are about to leave Aurigene Pharmaceutical Services and affiliates website. Aurigene Pharmaceutical Services assumes no responsibility for the information presented on the external website or any further links from such sites. These links are presented to you only as a convenience, and the inclusion of any link does not imply endorsement by Aurigene Pharmaceutical Services.

If you wish to continue to this external website, click Proceed.

Leaving already?

Don't forget to join us at

CPHI Worldwide 2023.

October 24th-26th, 2023 | Barcelona, Spain

Get ready to accelerate your drug’s journey to the market